Product note Pulleys Dodge engineered conveyor pulleys

Dodge engineered class conveyor pulleys offer the ultimate in reliable performance and economy. With more than 100 years of pulley engineering experience, Dodge pulleys are designed to deliver reliability in even the toughest applications. Engineering capabilities include: − Dedicated pulley design engineers − Finite element modeling

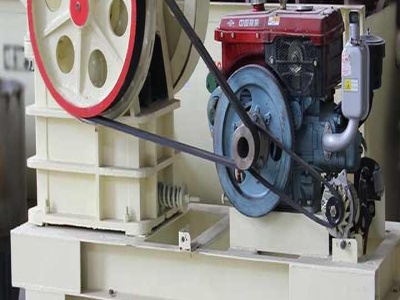

![How to Design a Flat Belt Drive [Tutorial] «](/rkv6us9/299.jpg)

![How to Design a Flat Belt Drive [Tutorial] «](/rkv6us9/24.jpg)